Our multipurpose houses are designed and manufactured in accordance with all quality requirements applied to industrial products. As automotive-grade waterproof technology is applied, they provide excellent airtightness, waterproofness, sound insulation and comfort.

Even without professional workers, it can be completed in 3~5 days with simple instructions.

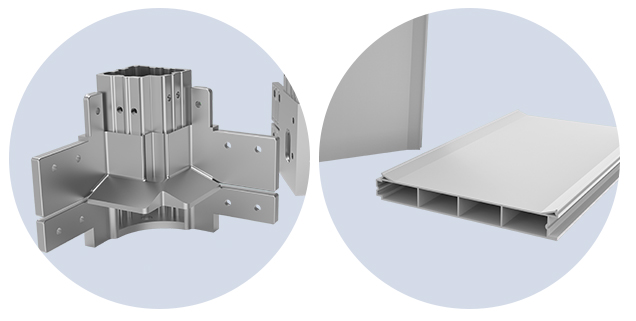

The parts (parts) of the house are built into a house like building blocks, and the construction can be done with a wrench. Even without professional workers, it can be completed in 3~5 days with simple instructions.

The house components are all prefabricated in the factory and are manufactured by extrusion, die-casting, and numerical control processing. The precision of the house components is guaranteed, and the error is only millimeters. The pure assembly construction is realized. The components are connected by screws without nailing or glueing. , greatly shorten the construction period.

There are both the comfort of a permanent building and the flexibility of a temporary building.

The house adopts a pure assembly installation method, which can be dismantled and reassembled. The main components can be re-melted and re-made, crushed and re-made, basically without loss, and can be used repeatedly.

Comes with decoration, install and live

The wall material is extruded under a high temperature and high pressure environment of 260°C. Generally, harmful gases such as formaldehyde have been completely volatilized at 160°C. The board has no formaldehyde residue, and the wall has its own interior decoration.

Multi-purpose Houses are designed and manufactured according to the quality requirements of industrial products. As automotive-grade waterproof technology is applied, they provide excellent air tightness, waterproofness, sound insulation and comfort.

The use of multi-cavity panels, combined with wall filling technology, can effectively keep heat and heat insulation. Compared with the brick-concrete structure, the heat transfer efficiency is lower, warm in winter and cool in summer; house materials are fireproof, moisture-proof and insect-proof.

Because magnesium-titanium alloy aluminum has strong toughness and is not easy to break, it offsets seismic wave energy, and all components are connected by screws (non-rigid connection)

Under standard construction, it can resist earthquakes (level 9 on mercalli intensity scale) and typhoon (level 16). It can also be strengthened according to customer requirements to achieve a higher level of seismic and wind resistance; the building structure has high strength, good toughness, and magnesium-titanium alloy Aluminum does not contain iron, does not rust, has excellent anti-corrosion and weather resistance, and has a service life of more than one hundred years without maintenance.

Material recycling rate : More than 95%

In the long run, due to inflation, the rise of non-ferrous metals is an inevitable trend. Materials will not only maintain their value, but will also increase in value in the future.

Integrated application of high-end technologies such as house comfort system, security system, intelligent system, renewable energy system, environmental protection system, etc.

Applicable to cultural tourism, health care, homestay hotels, commercial buildings, public buildings, sales showroom, military barracks Miner camp, border watchhouse and floating houses, etc.